How to Open an STL File A Practical Guide for Any Device

Struggling with how to open an STL file? Our guide covers the best free viewers, slicers, and browser tools for Windows, Mac, Linux, and online access.

Sambungan Disyorkan

So, you have an STL file and need to open it. The good news is you have plenty of options, from tools already on your computer to powerful, free software.

For a quick peek, your operating system’s built-in tools like Windows 3D Viewer or macOS Preview work just fine. If you need more functionality, dedicated free programs like Blender or MeshLab are fantastic. Of course, if 3D printing is your goal, slicer software like Cura or PrusaSlicer is the way to go since they not only open the file but also get it ready for your printer. You can even use a simple browser-based viewer for a no-install solution.

Before we dive into how to open these files, let’s quickly cover what they actually are.

What Is an STL File, Really?

At its core, an STL (which stands for Stereolithography) file is a straightforward, universal format that describes the surface geometry of a 3D object. It doesn't care about color, texture, or material—just the raw shape.

The file achieves this by breaking down the model's entire surface into a collection of interconnected triangles. This process is called tessellation. Think of it like creating a mosaic; enough small, flat triangles can approximate any complex curve.

This simplicity is precisely why the STL format is the bedrock of 3D printing. It's the lingua franca of the 3D world, understood by practically every 3D modeling program and printer out there. It’s the .txt file of 3D—basic, but it gets the job done everywhere.

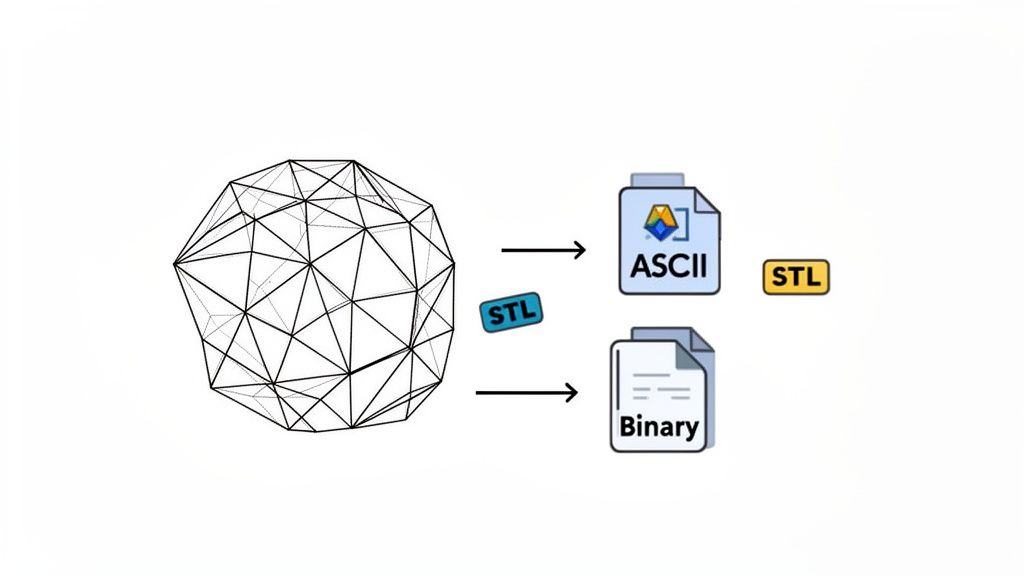

The Two Flavors of STL: ASCII vs. Binary

When you get an STL file, it will be in one of two formats: ASCII or Binary. They both describe the exact same model, but they store the data very differently, which has a huge impact on file size and how quickly the file loads.

- ASCII STL: This version is human-readable. You could open it in a basic text editor and see plain text coordinates for every single triangle. While that's great for manual debugging, it’s incredibly inefficient and results in enormous file sizes.

- Binary STL: This is the format you’ll encounter 99% of the time. It stores the same geometric data in a compact, machine-readable binary code. The result? A much smaller file that loads way faster.

For example, if a product designer is sending a prototype to a colleague, they will always use a Binary STL. The smaller size and faster loading are essential for a smooth workflow, especially with complex, high-poly models.

Why the STL Format Is Still a Big Deal

The STL format has been around since 1987, created by Chuck Hull and his team at 3D Systems for the very first stereolithography machines. It was a foundational invention for additive manufacturing.

Even with newer formats that can store color and material data (like 3MF or OBJ), the STL file’s unmatched cross-platform compatibility keeps it indispensable. It just works—with almost any software and hardware, making it a go-to for hobbyists and seasoned professionals alike.

A solid grasp of what STL files are is also critical for professionals in fields like 3D architectural rendering services, where these files are a common part of the design and visualization pipeline. With that foundation set, let's explore the best tools for the job.

Quick Guide to Opening STL Files

To give you a quick overview, this table summarizes the easiest and most common ways to view an STL file, depending on your needs.

| Method | Best For | Platform | Key Feature |

|---|---|---|---|

| Native OS Viewer | Quick, simple viewing without installation. | Windows, macOS | Instantly available on your computer. |

| Dedicated 3D App | Editing, analysis, and advanced viewing. | Windows, macOS, Linux | Powerful features like mesh repair and editing. |

| Slicer Software | Preparing a model for 3D printing. | Windows, macOS, Linux | Converts the 3D model into printer instructions (G-code). |

| Browser-Based Viewer | Viewing on any device without downloading software. | Any (Web-based) | Ultimate accessibility and easy sharing. |

Now that you have a high-level view, we can get into the specifics of each method.

Opening STL Files Instantly in Your Browser

Sometimes, the best tool is the one you don’t have to install. When you just need to quickly check a model, downloading and launching a full-blown desktop application can feel like using a sledgehammer to crack a nut. The fastest way to pop open an STL file is often right inside your web browser.

This is a lifesaver for rapid-fire workflows. Picture a QA engineer who has to verify a dozen different 3D models from a secure, locked-down machine. Installing bulky software might be impossible. A browser-based viewer lets them just drag and drop each file, inspect it, and move on in seconds.

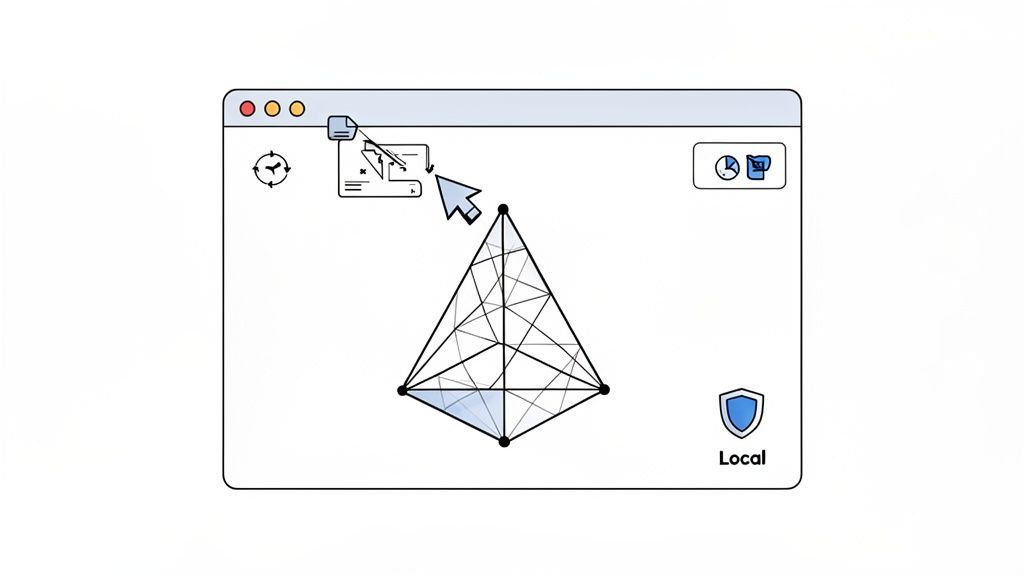

The Power of Local Browser Processing

One of the best things about modern browser tools is that they process files locally. This is a huge deal. It means your 3D models never leave your computer. They aren’t uploaded to some random server, which is a critical detail for privacy and security. It also means you can still open and view files even if your internet connection is flaky.

It wasn't always this easy. Years ago, opening an STL file meant firing up proprietary 3D Systems software. Today, with over 70% of 3D printing workflows relying on the STL format, you can do it effortlessly in your browser using tools like ShiftShift Extensions' 3D Model Viewer. This Chrome extension lets you drag and drop both ASCII and Binary STL files right into a browser tab for immediate interaction. Everything is processed locally, so your data stays yours. You can learn more about how the STL format continues to shape 3D printing on firstmold.com.

The key takeaway is speed combined with security. Browser-based viewers give you the instant access of an online tool without the privacy trade-offs of uploading sensitive design files to a third-party server.

What to Expect from a Browser Viewer

Most quality browser viewers give you a core set of interactive features that are surprisingly powerful for such a lightweight solution. You can typically handle all the essential inspection tasks without any lag.

For example, the ShiftShift 3D Model Viewer is accessed through a simple command palette. From there, you just drag your file right into the window.

The interface is clean and gets straight to the point, focusing on the model itself with controls that don't get in your way. Once loaded, you can get right to your inspection.

You'll have the standard controls that make a quick review a breeze:

- Rotate and Pan: Just click and drag with your mouse to orbit the model and view it from any angle.

- Zoom: Use your mouse's scroll wheel to get a close-up look at specific details or pull back for a full overview.

- Toggle Views: Switch on helpful overlays like a wireframe to see the underlying mesh or a grid and axes for spatial reference.

These tools are more than enough for most quick-check scenarios, like verifying a model you downloaded before sending it to your slicer or confirming a design revision from a colleague. If you want to dig deeper, you might be interested in our full breakdown of the features of a browser-based 3D model viewer.

Sometimes, you need more horsepower than a browser can offer. For those moments, a dedicated desktop application is the way to go. The great news is you probably already have a simple STL viewer installed on your computer, whether you know it or not.

Both Windows and macOS come with built-in tools that can handle a quick 3D model preview. These are perfect for those "just checking" moments—like when a colleague sends you a file and you just need to glance at it to make sure it's the right version. They load instantly and give you basic rotation and zoom controls without any overwhelming features.

Your Operating System's Built-in Tools

If you're on Windows, the 3D Viewer app is your best friend. It’s clean, simple, and usually the default program for STLs, so a quick double-click is all it takes. Once inside, you can easily spin the model around with your mouse and inspect it from every angle. It's surprisingly handy for a pre-installed app.

For macOS users, the built-in Preview application has some 3D viewing capabilities. It can open an STL, but honestly, it’s a bit basic compared to the Windows equivalent. If you find Preview's features a little underwhelming, a quick trip to the Mac App Store will turn up plenty of free, dedicated STL viewers that offer a much richer experience.

Leveling Up with Free and Powerful Software

When you need to do more than just look at a model, it’s time to call in the heavy hitters: free, open-source desktop software. These programs are the workhorses for hobbyists and professionals alike, packed with features for everything from mesh inspection to full-blown 3D editing.

The STL format has been around since 1987, and its incredible longevity is a testament to its simple utility. It has become the universal language of 3D printing, powering an estimated 90% of rapid prototyping workflows. This simple file format has been a key driver in the industry's explosive growth from $3.5 billion in 2015 to a projected $25 billion by 2025—a staggering 620% leap. Its universal compatibility is what makes it so powerful. You can learn more about the history and impact of the STL format) to see just how far it's come.

If you're ready to move beyond the basics, here are a few of the best free options out there.

Free Desktop STL Viewer Comparison

Choosing the right free tool can feel overwhelming, but it really comes down to what you need to do with the file. Are you just looking, or are you fixing, modifying, or creating? This table breaks down my top three recommendations to help you pick the right one for the job.

| Software | Primary Use Case | Platform | Key Advantage |

|---|---|---|---|

| Blender | Creative modeling, animation, and complex mesh repair | Win/Mac/Linux | All-in-one powerhouse for almost any 3D task imaginable |

| MeshLab | Advanced mesh inspection, cleaning, and analysis | Win/Mac/Linux | The "Swiss Army knife" for scientifically precise mesh doctoring |

| FreeCAD | Parametric 3D design and mechanical engineering | Win/Mac/Linux | Great for converting STLs into solid models for design work |

Each of these tools has its own personality and strengths. Blender is the artist's studio, MeshLab is the engineer's lab, and FreeCAD is the designer's workshop. Let's dig a little deeper into what makes each one tick.

Blender: Most people know Blender as a professional suite for creating stunning animations and visual effects, but it’s also a fantastic tool for handling STLs. To get your file in, just navigate to

File > Import > Stl (.stl). The learning curve for its controls can be a little steep, but its powerful mesh analysis and repair tools are second to none for a free program.MeshLab: This is a specialist's tool, designed from the ground up for processing and editing 3D triangular meshes. For engineers and researchers, it's a dream come true. It offers advanced features for cleaning up messy scans, healing holes, and inspecting models to ensure they're perfectly watertight and ready for printing.

FreeCAD: As a parametric 3D modeler, FreeCAD shines when it comes to engineering and product design. You can import an STL and even convert the mesh into a solid shape that you can then modify with precision. This makes it the perfect choice if your goal is to integrate an existing STL into a larger mechanical assembly.

The right tool really just depends on your end goal. If you just need a quick peek, stick with your operating system's default viewer. For serious pre-print analysis and repair, MeshLab is your go-to. And for creative editing or integrating a model into a bigger design project, you can't go wrong with Blender or FreeCAD.

Bringing Your STL to Life: Slicer Software for 3D Printing

If you've got a 3D printer, opening an STL file isn't just about looking at a model—it's about turning a digital blueprint into a real, physical object. This is where slicer software comes in, and tools like Cura and PrusaSlicer are your command center.

Importing the STL is just the first move. The real work happens next, as you strategically position the object on the virtual build plate. This isn't just a matter of making it fit; the model's orientation impacts everything from structural integrity to the amount of support material needed. Getting it right can dramatically cut down your print time and filament costs.

From Digital Model to Physical Object

Once the model is loaded, the slicer's magic truly begins. These programs don't just display the file. They analyze its geometry, allowing you to "slice" it into hundreds or even thousands of individual horizontal layers. You then get to preview the entire print process, one layer at a time.

This preview function is a game-changer and an indispensable diagnostic tool. Say you're printing a functional part, like a custom bracket. By scrubbing through the layer-by-layer view, you can:

- Spot potential weak points: Catch thin walls or tiny features that are likely to fail during the print.

- Check your infill: Make sure the internal structure is strong enough for your needs without wasting material.

- Verify the toolpath: Watch the nozzle's exact travel path to spot potential problems like unnecessary retractions or collisions with the model.

Spending a few minutes inspecting the sliced model this way can save you hours of frustration and a spool of wasted filament. It's often the difference between a perfect prototype and a spaghetti monster on your print bed.

Automatic Repairs and Getting Print-Ready

Modern slicers are incredibly smart. They come packed with powerful algorithms that automatically find and fix common mesh problems that would otherwise doom a print. Issues like tiny holes or non-manifold edges often get patched up the moment you import the file, sometimes without you even noticing.

A slicer's core job is to bridge the gap between a 3D model (the STL) and the precise, machine-readable instructions your printer needs (the G-code). It crunches all the complex numbers so you can focus on getting the best possible physical result.

For pros on tight deadlines, speed is everything. This is why binary STL files are the go-to format in 80-90% of professional workflows. They can be up to 90% smaller than their ASCII counterparts, which means they load almost instantly in slicers. That efficiency is a huge advantage when you're churning through hundreds of files a day. You can find more practical tips on STL file optimization at firstmold.com.

Ultimately, knowing how to open an STL file in a slicer is the most fundamental skill for anyone in 3D printing. It’s the critical step where you give a static model its path into the physical world, tweaking every last detail to nail the perfect print.

How to Fix Common STL File Problems

So, you’ve got an STL file, but it’s giving you grief. Maybe your slicer is throwing up errors, your viewer is showing weird graphical artifacts, or worse, your 3D print is failing. Don't worry—most of these issues come from a few common geometry problems that are actually pretty easy to fix once you know what to look for.

Think of an STL file as a digital sculpture made of thousands of tiny, connected triangles. For it to print correctly, it needs to be "watertight." That means every single edge of every triangle must be perfectly stitched to exactly one other triangle's edge. When that simple rule is broken, things get messy.

But a broken model isn’t a dead end. With the right tools and a bit of insight, you can patch up a faulty STL in just a few minutes and get your project back on track.

Diagnosing and Repairing Mesh Errors

The usual suspects behind a problematic STL are non-manifold geometry, flipped normals, and intersecting faces. These sound a bit technical, but the concepts are simple. Most modern 3D software can spot these problems for you, but knowing what they are helps you fix them faster.

Here's a breakdown of what you'll typically run into:

- Non-Manifold Geometry: This is just a fancy way of saying there are holes or gaps in your model. Imagine a tiny pinhole in a balloon—it's no longer airtight. A slicer will often flag this because it can't figure out what's supposed to be the "inside" of the model versus the "outside."

- Flipped Normals: Every triangle in your mesh has an "in" side and an "out" side, defined by its normal vector. A flipped normal means a triangle is facing the wrong direction, creating what looks like a hole and confusing the slicer about where the solid material should be.

- Intersecting Faces: This happens when two or more triangles cut through each other, creating geometry that can't exist in the real world. It's like trying to push two solid objects through one another, and it can cause some seriously ugly artifacts in your final print.

The good news? Many modern slicers like Cura and PrusaSlicer have gotten pretty smart. They often have built-in repair functions that automatically fix a huge percentage of these common errors when you import the file. For more stubborn problems, a dedicated tool like MeshLab gives you more powerful, hands-on repair options.

Your Go-To Troubleshooting Workflow

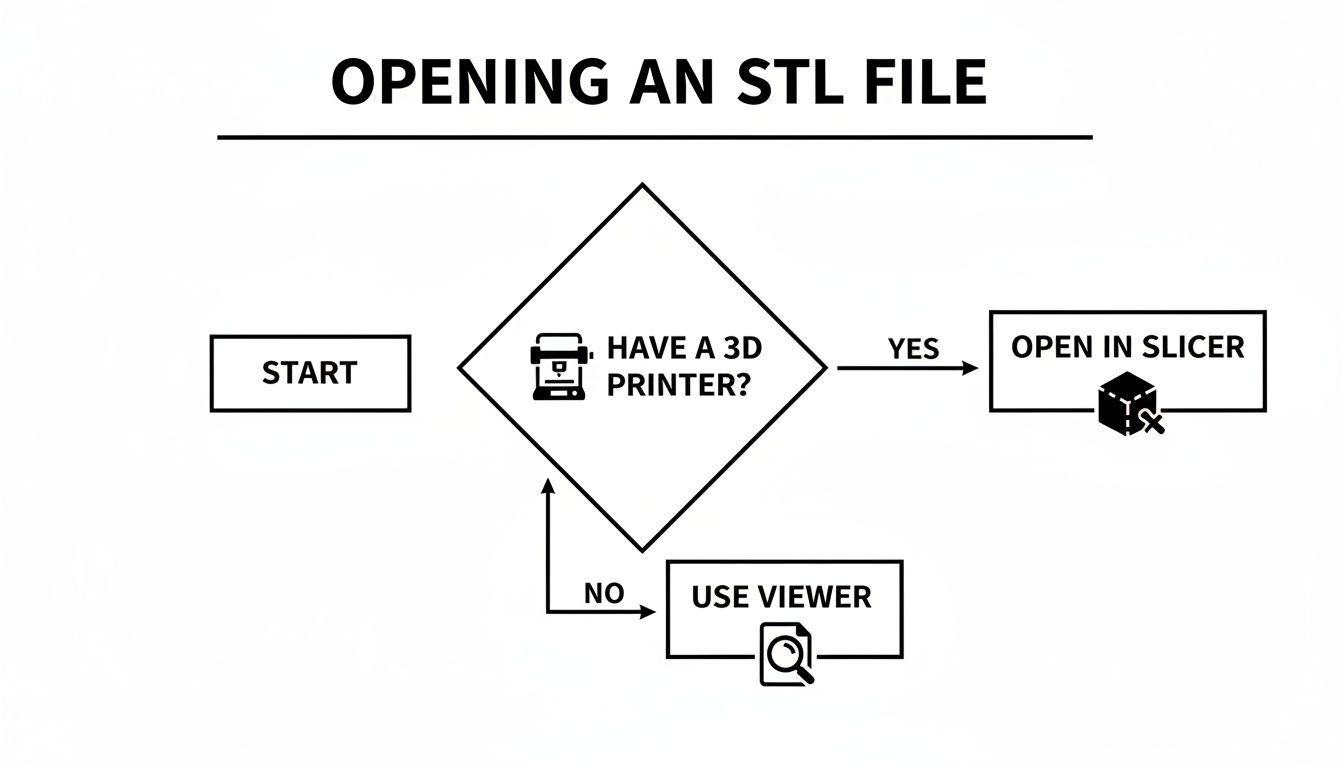

When you hit a snag with an STL, the first step is to figure out where to open it. This simple decision tree shows the most common path people take when opening and preparing a model.

As you can see, the path forks early: if you’re 3D printing, your slicer is the main tool. If you just need to inspect the model, a simple viewer will do the trick. Thinking this way keeps your workflow efficient.

Even with newer formats like 3MF appearing in 2015, the STL format has stuck around. Why? Its universal backward compatibility is a massive advantage, protecting years of investment in older hardware and software. This is a big reason why an estimated 2.5 billion STL files are still exported every year around the globe. You can read more about the enduring legacy of the STL format on Wikipedia).

Whether you're repairing a complex CAD model or just doing a quick visual check, understanding these potential issues makes working with STL files a whole lot smoother.

Got Questions About STLs? We've Got Answers

Diving into 3D models often brings up a few common questions, especially when you're just getting your bearings. This is your go-to spot for quick, no-nonsense answers about handling STL files. Let's clear up the confusion so you can get back to creating.

So, Can I Actually Edit an STL File?

Yes, but it's not quite like editing a Word doc. Think of it this way: while a simple viewer lets you look but not touch, dedicated mesh editing software like Blender, Meshmixer, or FreeCAD gives you the tools to make changes.

An STL file is just a mesh—a collection of interconnected triangles. It isn't a "smart" parametric model from CAD software. This means editing involves pushing, pulling, and sculpting those triangles directly. This "direct modeling" approach is fantastic for artistic tweaks, repairing holes, or smoothing a rough surface. It's less ideal for precise engineering changes, like trying to change a bolt hole's diameter by exactly 0.5mm.

How Do I Convert an STL to Something Else?

Switching an STL to another format like STEP or OBJ is a super common need, and most serious 3D programs can do it. The best tool really depends on what you're trying to accomplish.

- Need a CAD file (like STEP)? FreeCAD is your friend here. You can import the STL mesh, use its tools to create a solid body from that mesh, and then export it as a STEP file. Now it's ready for proper engineering software.

- Need another mesh format (like OBJ)? If you're moving to a format that handles color and textures, Blender is perfect. The workflow is dead simple: import the STL, then go to

File > Exportand choose OBJ.

A word of caution on online converters: while convenient, think twice before uploading sensitive or proprietary designs to a random website.

Pro Tip: For any professional or confidential work, stick to desktop software for conversions. You maintain full control over your intellectual property and won't run into the file size limits that often hamstring free online tools.

Why Is My STL File Completely Gray?

Ah, the classic question! This gets to the very heart of what an STL file is. The original STL format was designed with a single purpose in mind: to describe the raw, 3D surface geometry of an object. That's it.

It contains absolutely no information about color, textures, or what material it's supposed to be made of. It's just a list of coordinates for the triangle vertices that form the model's shell. If you need color, you'll have to use a more capable format like OBJ, 3MF, or FBX.

What's the Deal with "High" vs. "Low" Resolution?

When we talk about "resolution" for an STL file, we're really talking about the density of its triangle mesh. It's all about the detail.

A high-resolution STL file uses a massive number of tiny triangles to map out the surface. This captures fine details and creates beautifully smooth curves, but the tradeoff is a huge file size. On the flip side, a low-resolution STL uses fewer, larger triangles. The file is much smaller and easier to handle, but curves can look blocky or faceted. Choosing the right one is always a balance between visual fidelity and performance.

Ready to supercharge your browser workflow? ShiftShift Extensions offers a growing suite of powerful tools—from a 3D Model Viewer to code formatters—all accessible through a single, lightning-fast command palette. Try it for free at https://shiftshift.app.