How to Open a stl File: A Practical Guide for Any User

How to open a stl file: discover the best free viewers, browser tools, and CAD software for 3D printing and design.

Önerilen Uzantılar

So, you've got an STL file and need to open it. The good news is, you have plenty of options. You can use free desktop software that’s likely already on your computer (like Microsoft 3D Viewer on Windows), upload it to a web-based viewer for a quick peek, or pull it into a full-blown CAD or 3D printing slicer program.

The right tool really boils down to what you need to do with the file. Are you just giving it a once-over, or are you prepping it for a 3D print or making design changes?

Understanding Your STL Viewing Options

Before you download the first program you find, let's break down the different types of tools available. Your goal is everything here. A quick design verification calls for a different approach than integrating that same model into a complex engineering assembly.

It's pretty amazing that the STL format is still the king of 3D printing. It was first developed way back in 1987 by 3D Systems for their original stereolithography printers. It's a simple concept—approximating a 3D surface with a mesh of triangles—but it works incredibly well. That's why it's still used in over 90% of 3D printing workflows today. If you want to get into the weeds of its history and structure, there are some great comprehensive overviews of the STL file format out there.

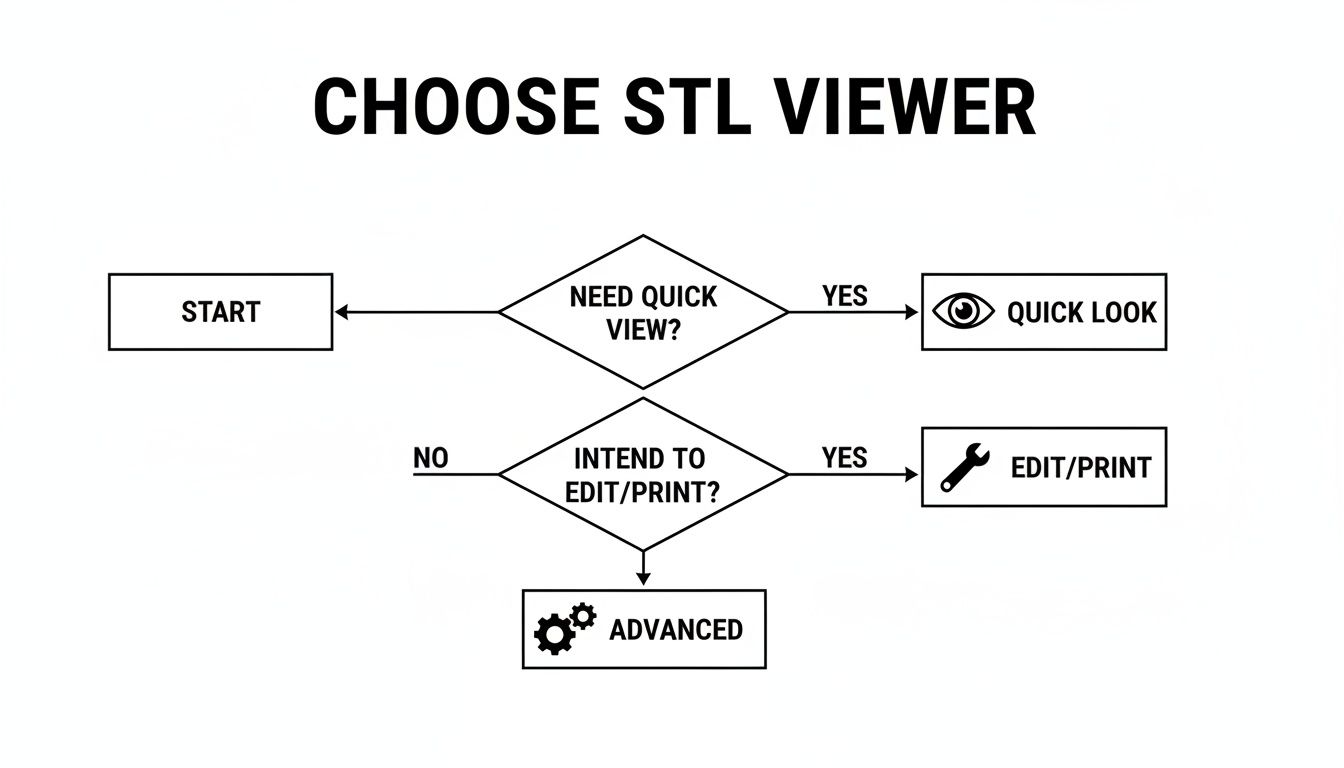

Choosing Your Path: Quick Look, Edit, or Advanced?

To cut through the noise, just ask yourself what you need to accomplish right now. This flowchart maps out the decision-making process based on the most common tasks.

As you can see, if you just need to inspect a model, a simple browser tool or a basic desktop viewer is your fastest bet. But the moment you need to make changes or prepare a file for printing, you'll need to jump into a slicer or a proper CAD program. For heavy-duty analysis, you're looking at specialized engineering software.

Three Quick Ways to Open Your STL File

To give you a clearer picture, I've put together a table comparing the three most common ways to pop open an STL file. Each method has its own sweet spot when it comes to speed, features, and—importantly—privacy.

| Method | Best For | Speed | Key Features | Privacy Level |

|---|---|---|---|---|

| In-Browser Viewers | Instant, secure model inspection without installation. | Very Fast | Rotate, zoom, wireframe view, screenshots. | High (with local viewers) |

| Desktop Software | Offline viewing and more powerful inspection tools. | Fast | Measurement tools, mesh analysis, basic repairs. | Very High |

| Full CAD Programs | Editing, modifying, and integrating models into projects. | Slower | Full editing suite, file conversion, assembly. | Very High |

This table shows a clear trade-off: for sheer speed and convenience, nothing beats a browser-based viewer. But for more control and advanced features, you'll want dedicated software installed on your machine.

My Two Cents: If you just need to see what's inside an STL file quickly and securely, a local in-browser viewer like the one from ShiftShift Extensions is the way to go. It’s unbeatable. You don't have to download anything, and more importantly, your design files never leave your computer. For sensitive or proprietary projects, that’s a huge win. For anything beyond a simple look, you’ll need to fire up your desktop software.

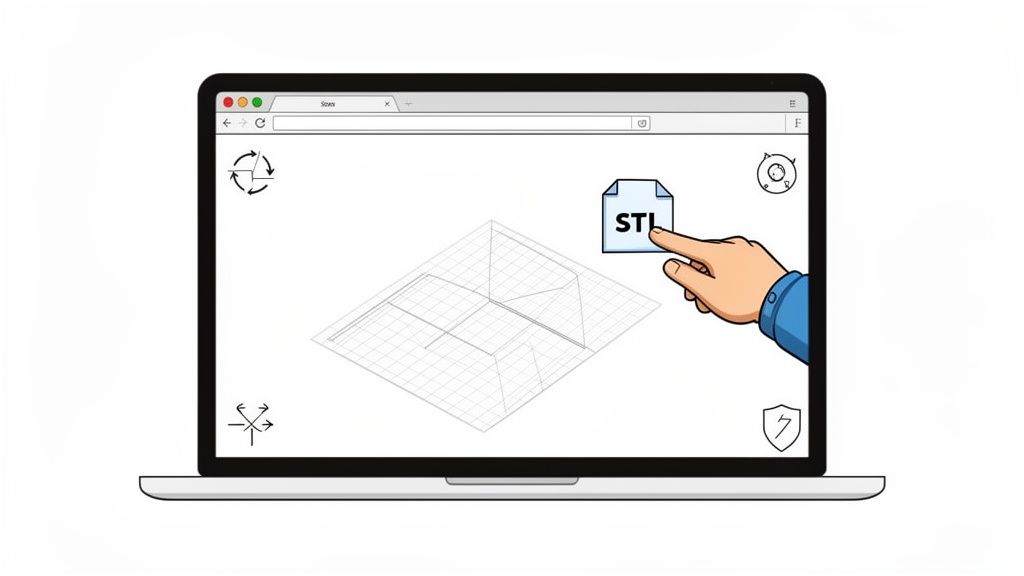

Opening STL Files Instantly in Your Browser

Sometimes you just need to see what's in an STL file, and you need to see it now. Forget waiting for bulky software to install or asking your IT admin for permissions. The quickest way is often already open on your screen: your web browser.

This is a game-changer, especially when you're handling sensitive or proprietary designs. A lot of online viewers make you upload your file to their servers, which can be a huge security red flag. The best ones, however, run everything right on your own machine. Your intellectual property never leaves your computer.

A Privacy-First Workflow

The trick is to find a viewer that uses your browser's own power to process the file locally. This privacy-first workflow is beautifully simple: open the tool's webpage or extension and just drag and drop your STL file. All the heavy lifting and rendering happens right there on your device, keeping everything completely confidential.

Imagine an engineer needing to review a confidential prototype. They can open the STL file securely without ever sending it to a third-party cloud. Or think of a product designer who needs to quickly check a model from a freelancer without cluttering their work machine with another program. It’s clean, secure, and incredibly efficient.

A local in-browser viewer eliminates the friction between receiving a file and seeing it. You're not just saving time; you're adopting a workflow that inherently protects your data by keeping it off external servers entirely. This is a non-negotiable for professionals working with pre-release or confidential designs.

This approach effectively turns your browser into a powerful, on-demand tool for anyone who needs to know how to open a stl file without the typical software overhead. For a deeper dive into why this is so effective, check out our guide on the advantages of a browser-based 3D model viewer.

Essential Features for Quick Checks

Now, these viewers aren't meant to replace a full-blown CAD program, but they pack all the essential features you'll need for rapid inspection and verification. Honestly, these are the core functions you'll use 90% of the time.

You get instant access to the fundamental controls that let you examine a model from every conceivable angle. They’re perfect for confirming a design is correct before you send it off for printing or pass it along to the next person in the chain.

Here’s what you should expect from any good in-browser viewer:

- Model Rotation: Freely spin the model on the X, Y, and Z axes for a complete 360-degree look.

- Zoom and Pan: Get up close to inspect tiny details or slide across the model to check different areas with ease.

- Wireframe View: Switch between solid and wireframe modes. This is my go-to for analyzing the underlying mesh and spotting potential geometry problems.

- Screenshot Capture: Grab a quick, high-quality snapshot of your current view to share with a colleague or client for instant feedback.

These tools make everyday tasks a breeze—like verifying a part’s orientation, spotting obvious surface flaws, or just making sure you've got the right file before moving forward. It’s a lightweight but absolutely indispensable solution.

Choosing the Right Desktop STL Viewer

Sometimes, a quick look in your browser just won't cut it. For a deeper dive, you'll want a dedicated desktop application. These programs are built for performance, work offline, and pack the serious tools you need for detailed inspections, all without the lag of a web app. Think of it as the next logical step when you need to do more than just glance at a model.

The real trick is matching the software to what you actually need to do. If you're a hobbyist just trying to make sure a file looks right before you hit "print," you don’t need a complex engineering suite. On the flip side, a barebones viewer will fall short if you’re trying to take precise measurements or hunt down flaws in the mesh.

For Windows Users: A Built-In Solution

If you're on a Windows PC, good news—you probably already have a great tool ready to go. The Microsoft 3D Viewer comes pre-installed on Windows 10 and 11, and frankly, it's pretty solid for a default app. It handles STL, OBJ, and other common formats smoothly, with clean rendering and simple controls.

Honestly, this is the first thing I recommend to any Windows user. It's the path of least resistance. You can open an STL, spin it around, check its dimensions, and even play with some basic lighting. For a quick, thorough check, it's often all you'll ever need.

Cross-Platform Powerhouses for All Users

When you need to get more serious, or if you're on macOS or Linux, it’s time to look at specialized, cross-platform viewers. These apps are designed from the ground up for handling complex 3D mesh data and are loaded with features that go way beyond simple viewing.

Two free options really stand out in this space:

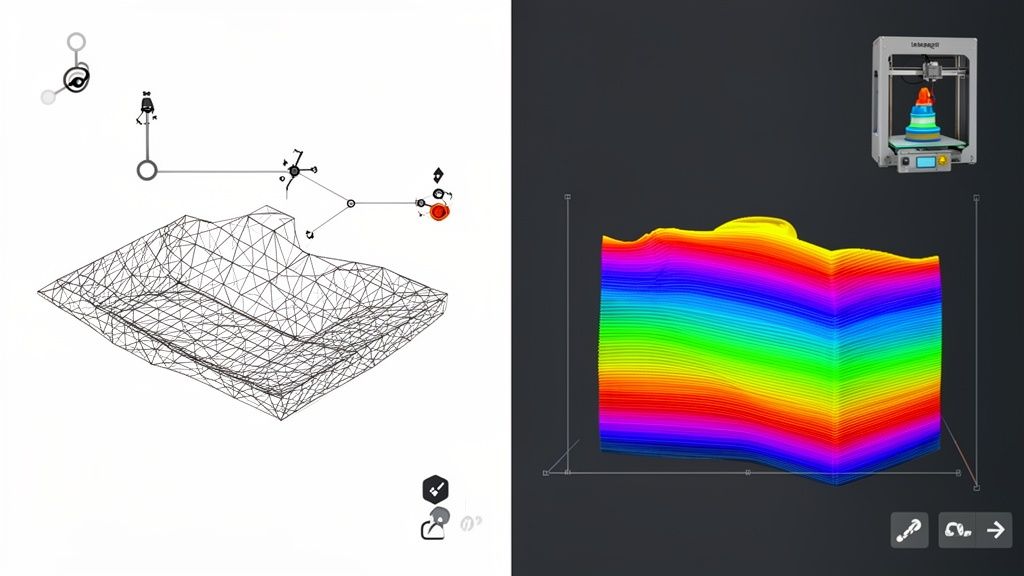

- MeshLab: I often call this the "Swiss Army knife" for 3D meshes. It’s an open-source powerhouse that’s so much more than a viewer. You can use it to clean up, edit, repair, and truly analyze 3D models.

- UltiMaker Cura: While its main job is a slicer for 3D printing, Cura is also a fantastic STL viewer. Because it's designed to get models ready for printing, it's incredibly good at spotting potential issues that other viewers might miss.

This screenshot of the MeshLab interface gives you a sense of its power. The sheer number of tools visible shows it's built for deep analysis, far beyond what a basic viewer can do.

Making the Right Choice for Your Workflow

So, how do you pick the right tool? It all boils down to your primary goal. You want something that solves your problem without overcomplicating your life.

Pro Tip: Don't install three different programs when one will do the job perfectly. Start with the simplest tool that meets your immediate need. For Windows users, that's 3D Viewer. Only when you hit its limits—say, you need to fix a broken mesh—should you move up to something like MeshLab.

Think about your most common tasks:

- Quick Verification: Just need to confirm you downloaded the right file and it looks okay? Microsoft 3D Viewer (Windows) or the Preview app (macOS) is perfect.

- Detailed Inspection: Need to take measurements, check wall thickness, or look for surface defects? A precision tool like MeshLab gives you the control you need.

- Print Preparation: If you're heading straight to the 3D printer, just open the STL in your slicer like Cura. You can view the model and prep it for printing all in one go. It’s the most efficient workflow.

Using CAD and Slicer Software for STL Files

When you need to do more than just look at a model, it’s time to move beyond simple viewers. For serious modification or getting a file ready for 3D printing, you'll need to step up to professional tools like Computer-Aided Design (CAD) or slicer software. These applications are built to turn a digital file into a real-world object.

Importing an STL into a CAD program like Fusion 360, Blender, or SolidWorks is a completely different ballgame. The software doesn't see an intelligent, editable object with a build history. Instead, it sees a "dumb" mesh—a hollow shell made of countless interconnected triangles. It’s a snapshot of the final geometry, but all the parametric data that created it is gone.

This distinction is everything. The STL format’s simplicity is both its greatest strength and its most significant weakness. By design, it strips away the sensitive design history, which can reduce data transfer by up to 99% compared to a format like STEP. This intentional data protection has been a huge driver in the rapid prototyping market—projected to hit $15 billion by 2025—because it lets companies share models without giving away their intellectual property.

Making an STL Editable in CAD

Since an imported STL is just a mesh, editing it directly can be tricky. Think of it like trying to edit a flattened JPEG versus a layered Photoshop file. You can't just click a hole and type in a new diameter. However, modern CAD packages have powerful mesh-editing tools to help you get the job done.

Here are a few common ways to tackle it:

- Direct Mesh Manipulation: Many programs let you push, pull, and sculpt the triangular faces. This approach works beautifully for organic shapes or making small artistic adjustments.

- Mesh-to-Solid Conversion: Some software will try to convert the mesh into a solid body. If it works, you can then use standard parametric tools to modify it. Be warned, though—this process can fail or create errors on more complex models.

If you plan on seriously modifying or creating STL files from scratch, getting comfortable with mastering 3D modeling software is a must.

The Role of Slicer Software

If your final destination is a 3D printer, a slicer is non-negotiable. Slicers like UltiMaker Cura, PrusaSlicer, or Bambu Studio are the last—and most critical—step in the digital workflow. Their main job is to "slice" your 3D model into hundreds or even thousands of thin horizontal layers.

A slicer translates the geometric shell of an STL file into a detailed, step-by-step instruction manual for your 3D printer. This manual, called G-code, tells the printer exactly where to move, how fast to go, and how much material to extrude for every single layer.

When you open an STL in a slicer, you’re not just viewing it; you're preparing it for fabrication. Here, you'll dial in the crucial settings that directly affect your final print's quality, strength, and appearance.

You'll be focused on key parameters like:

- Orientation: Deciding how the model sits on the build plate to ensure a successful print and minimize the need for supports.

- Infill: Defining the internal structure—balancing strength against how much material you use and how long the print takes.

- Supports: Automatically generating removable structures to hold up any overhanging parts of your model while it prints.

- Layer Height: Setting the thickness of each layer, which is a trade-off between fine detail and faster print speed.

Ultimately, CAD and slicer software are the essential tools that bridge the gap between a digital file on your screen and a physical object in your hands.

How to Fix Common STL File Problems

Sooner or later, you’ll run into an STL file that just refuses to cooperate. You try to open it and get an error message, a garbled mess of polygons, or worse, absolutely nothing. This happens all the time, and the good news is that most of these problems are totally fixable once you know what you’re looking for.

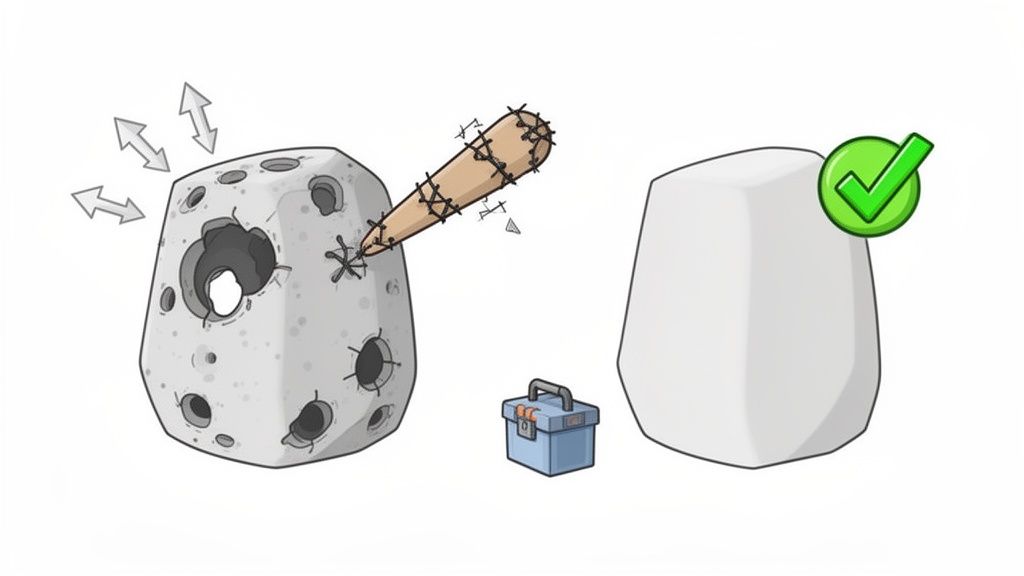

When you're trying to figure out how to open a stl file that seems broken, the issue usually boils down to a handful of common geometric errors. For a piece of software to make sense of a 3D model—especially for 3D printing—it needs to be a perfect, "watertight" digital object. Any holes, weird overlapping surfaces, or flipped triangles can completely confuse the program trying to render it.

Diagnosing and Fixing Your File

The usual suspects behind a fussy STL are almost always flaws in the geometry. Don't worry if the terms sound a bit technical; the concepts are pretty simple, and many free tools can fix these issues with a single click.

Here are the big three:

- Non-Manifold Geometry: This is the most common problem by far. Think of a single edge on your model that’s shared by three or more faces. In the real world, that's impossible, and it creates an ambiguity that software just can't handle.

- Inverted Normals: Every little triangle that makes up your model has an "inside" and an "outside." If some of these get flipped the wrong way, it can create what look like holes in the model or cause a 3D printing slicer to completely fail.

- Holes in the Mesh: Your model needs to be a completely sealed, continuous surface. Any gaps or holes mean it isn't watertight, which is a non-starter for 3D printing and can lead to strange visual glitches in viewers.

To wrestle these problems into submission, tools like Autodesk Meshmixer, the repair functions in Windows 3D Builder, and PrusaSlicer are your best friends. Most of them have a brilliant one-click "auto-repair" feature that analyzes the mesh and patches up these common errors for you.

My Go-To Fix: When a file is giving me grief, my first stop is PrusaSlicer. Even if I'm not planning to print anything, I'll just import the STL. It’s fantastic at spotting errors right away and will often pop up a message offering to fix them. Its repair algorithm is surprisingly robust and solves my problem about 80% of the time.

Understanding ASCII vs. Binary STL Files

Sometimes the problem isn't the model itself, but the file format. STL files actually come in two flavors: ASCII and binary. They both describe the exact same geometry, but the way they store the data is fundamentally different, and some older or specialized programs can only read one type.

Diving into the numbers, binary STL files aren't just popular—they're the workhorse of modern 3D printing. They can have file sizes up to 95% smaller than their ASCII counterparts, which is a massive difference. It's no surprise that industry stats show over 85% of STL files shared online are in binary format; they're just far more compact and quicker for machines to process. You can dig deeper into the importance of different STL file formats in 3D printing if you're curious.

- ASCII STL: This format is human-readable. You can literally open one in a text editor and see the coordinates for every single triangle written out in plain text. It’s great for troubleshooting but results in huge file sizes.

- Binary STL: This is the modern standard. It stores the same data in a much more compact, computer-friendly binary code. Files are dramatically smaller and load much, much faster.

If a program chokes on an STL file, it might simply be expecting the other format. A quick and easy fix is to open the file in a program like MeshLab and just re-save it as a binary STL. That simple conversion can clear up compatibility issues in an instant.

Your Questions About STL Files Answered

As we wrap up, let's tackle some of the common questions that always seem to come up when you're working with STLs. Getting a straight answer to these can save you a ton of frustration, especially when all you want to do is figure out how to open a stl file and get back to your project.

One of the first things people try to do is edit them. Can you just pop an STL into your favorite CAD software and start tweaking dimensions? Well, it's not quite that simple. The reason lies in how the file is fundamentally built.

Why Is Editing an STL So Hard?

At its core, an STL file is a mesh model. I like to think of it as a hollow object wrapped in a rigid, triangular net. It only describes the final surface of the model—the "skin," if you will. It has no memory of the steps taken to create it. This is a world away from a native CAD file, which is usually parametric.

A parametric model is more like a recipe. It logs every single step—every extrusion, every cut, every fillet—and lets you go back and change any of them. Want to make a hole 2mm wider? You just edit that specific feature. With an STL, that "recipe" is gone. You're left with the finished cake, and changing it means you have to manually push and pull the individual triangles of the mesh. It’s a messy, imprecise process.

STL vs. Other Common 3D Formats

The STL format has been the workhorse of 3D printing for decades, but it's not the only game in town. You'll frequently encounter formats like OBJ and 3MF, and understanding their strengths helps you pick the right one for the job.

| File Format | Key Feature | Best Use Case |

|---|---|---|

| STL | Geometry Only | The universal standard for 3D printing compatibility. |

| OBJ | Geometry & Basic Textures | Simple models that need color or texture information. |

| 3MF | Modern & Comprehensive | Complex, multi-part, or multi-color 3D printing jobs. |

As you can see, STL is your basic, reliable option when you just need the shape. If you need to include color data, OBJ is a solid step up. But for modern, complex projects that bundle materials, colors, and other print-specific data into one neat package, 3MF is the clear winner.

Why Are Some STL Files So Big?

Have you ever downloaded a seemingly simple model, only to find it's hundreds of megabytes? The file size of an STL really comes down to two things: its polygon count and its file type.

The more triangles used to approximate a model's surface, the more detail you get—and the larger the file becomes. A high-resolution model with lots of smooth curves can easily have millions of polygons, and every single one adds to the file size.

The format choice between binary and ASCII also makes a huge difference. Binary STLs store data much more efficiently and are the standard for a reason. An ASCII file, which is written in plain text you can read in a text editor, can easily be five or six times larger for the exact same model.

For a completely private, in-browser way to inspect your STL, OBJ, and other 3D models, check out the ShiftShift Extensions 3D Model Viewer. All the processing happens right on your machine, so your designs always stay yours. You can learn more at https://shiftshift.app.