How to Open STL File: how to open stl file in 3 Easy Steps

how to open stl file: Quick steps to view STL models on Windows, macOS, Linux, and online with free tools, no software purchase required.

Opening an STL file doesn't have to be a chore. The quickest way is to use a dedicated free viewer like MeshLab, pop it open with a built-in tool like the Windows 3D Viewer, or just drag and drop it into a browser-based viewer. All these methods let you inspect a 3D model in seconds, without wrestling with complex CAD software.

Your Quickest Path to Viewing an STL File

You've got an STL file, and you just need to see it. The last thing you want is to get bogged down installing a massive program just for a quick look. Whether you're a hobbyist double-checking a model before it hits the 3D printer or a professional giving a design a once-over, getting your eyes on it fast is what matters.

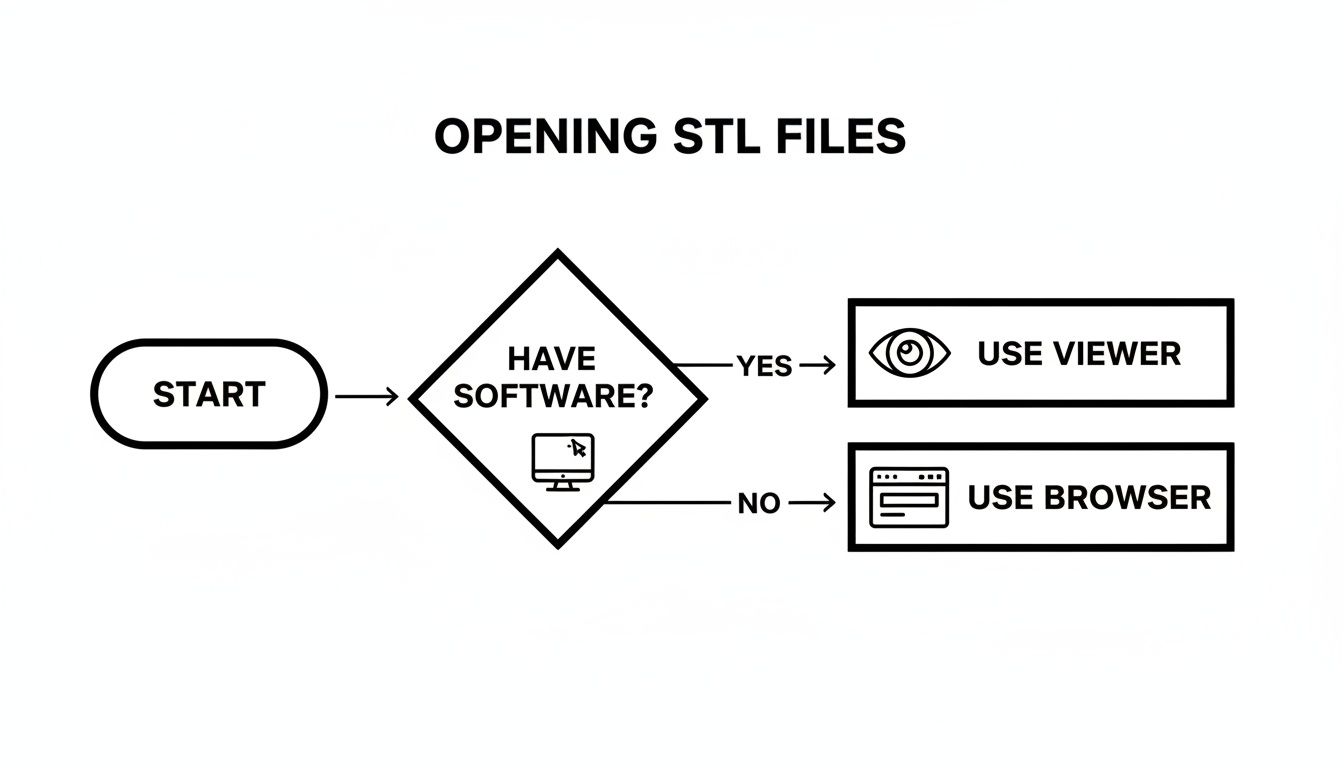

Thankfully, you've got a couple of great options right at your fingertips. The first is a lightweight, dedicated STL viewer—a simple app built for one job: opening 3D models efficiently. The second, and often even faster, route is a browser-based tool. These web apps require zero installation; you just drag, drop, and view.

Dedicated Viewers vs. Browser Tools

Dedicated viewers are perfect if you work with 3D models all the time and want a reliable, offline tool on your desktop. They often come with handy inspection features, like measuring tools or simple mesh analysis, but they're nowhere near as complicated as a full-blown CAD package. Think of them as a specialized magnifying glass for your 3D work.

On the other hand, browser-based viewers are all about convenience. They're ideal for those one-off tasks, for sharing a model with a colleague who doesn't have any 3D software, or for when you're on a computer where you can't install anything. With tools like the ShiftShift Extensions 3D Model Viewer, your file stays local to your browser, so you don't have to worry about your data being uploaded somewhere.

This simple flowchart lays out the decision-making process for getting your file open.

As you can see, it really just comes down to whether you prefer having a permanent tool on your machine or the instant-on accessibility of a web app.

Key Takeaway: For the absolute fastest result with zero setup, a browser-based viewer is the way to go. If you handle STL files daily, a dedicated desktop viewer is a smart addition to your workflow.

To help you decide at a glance, here’s a quick breakdown of the fastest methods.

Fastest Ways to Open an STL File

| Method | Best For | Platform | Cost |

|---|---|---|---|

| Browser-Based Viewer | Instant, one-off viewing; sharing and collaboration | Any (Web browser) | Free |

| Built-in OS Viewer | Quick checks without installing new software | Windows, macOS | Free |

| Dedicated Desktop Viewer | Frequent use; offline access; basic analysis tools | Windows, macOS, Linux | Free |

| 3D Modeling/CAD Software | When you need to edit or analyze the model in detail | Windows, macOS, Linux | Free to Professional |

Each of these tools gets the job done, but picking the right one for your situation will save you time and frustration. For most people, a browser or built-in OS viewer is more than enough for a quick preview.

Understanding What Makes an STL File Tick

Before you can get comfortable opening an STL file, it helps to know what’s actually going on under the hood. It might seem like a complex file type, but it’s surprisingly straightforward. At its core, an STL file describes the surface of a 3D object using a vast collection of triangles. This method is called tessellation.

Think of it like covering a soccer ball with tiny, flat triangular patches. Each patch is simple, but when you put enough of them together, they create the illusion of a smooth, curved surface. The more triangles you use, the smaller they are, and the more detailed your 3D model looks. It’s this elegant, no-frills approach that has kept the STL format a powerhouse in 3D printing for decades.

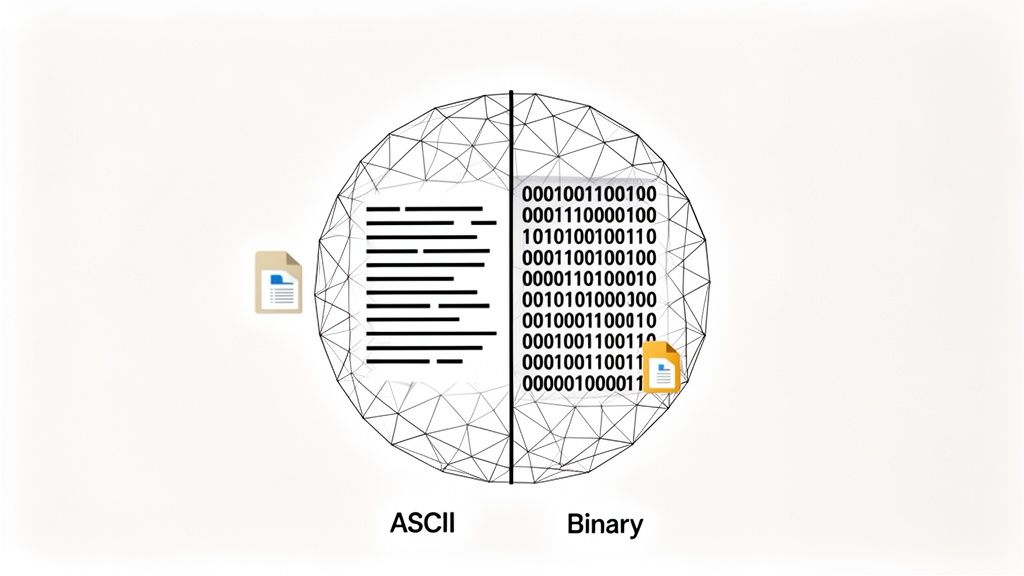

The Two Flavors of STL: ASCII and Binary

Every STL file you encounter will be one of two types. Understanding the difference is a great troubleshooting trick, as it often explains why one program opens a file just fine while another chokes on it.

- ASCII STL: This version is entirely text-based. You could literally pop it open in Notepad and see human-readable coordinates for every single triangle's vertices. This is fantastic for debugging or manually inspecting the file, but it comes at a cost: the files are huge.

- Binary STL: This is the format you’ll run into most of the time. It stores the exact same triangle data but in a much more compact, machine-readable binary code. These files are significantly smaller and faster for software to read, making them the industry standard for nearly every application.

Key Takeaway: If you ever hit an error trying to open an STL, one of the first things to suspect is the format. Some older, simpler viewers, or even specialized software, might only be built to handle one type—usually binary, thanks to its efficiency.

This brilliantly simple structure isn’t a recent invention; it dates all the way back to the birth of 3D printing. The STL file format was created in 1987 by 3D Systems, the company founded by the inventor of stereolithography, Charles Hull. Initially, "STL" was short for "Stereolithography," but its name has since been unofficially backronymed to "Standard Triangle Language" or "Standard Tessellation Language." You can read more about its origins and impact over at the FirstMold website.

So, when you open an STL file, you're not loading a complex visual model. Your software is just reading a long, simple list of triangles and putting them together in 3D space. That’s all there is to it.

Opening STL Files on Windows, macOS, and Linux

No matter what kind of computer you’re running, you can open and view STL files without much fuss. Most operating systems come with a built-in tool that works for a quick look, and for anything more serious, a massive community of developers offers powerful, free software.

Let's dig into the best options for each platform.

Viewing STL Files on Windows

If you're on a modern version of Windows—10 or 11—you're already set. You have a surprisingly capable STL viewer baked right in: the 3D Viewer app.

Just search for "3D Viewer" in your Start Menu to fire it up. From there, you can drag your STL file directly into the window. It gives you all the basic controls for rotating, panning, and zooming, plus a few handy lighting and shading options to help you really inspect the model's surface details.

For a much smoother workflow, I recommend making 3D Viewer your default program for STLs. It's a simple, one-time fix.

- Find any

.stlfile and right-click on it. - Go to "Open with" and then select "Choose another app."

- Pick "3D Viewer" from the list of programs.

- Make sure you check the box at the bottom that says "Always use this app to open .stl files."

That's it. Now, double-clicking any STL file will pop it open instantly. This little tweak saves a lot of time.

Handling STLs on macOS

Over on the Mac side, Apple provides a native solution for quick peeks. The trusty Preview app, which you already know from PDFs and images, can also open STL files. A simple double-click should be all it takes.

But let's be honest—Preview is pretty barebones. It shows you the model, and that's about it. If you need to do anything more than just confirm what the file is, you’ll want a dedicated tool. A fantastic free and open-source choice is MeshLab. It’s a beast of a program that pros use for cleaning up and editing 3D meshes, but it also happens to be a superb viewer.

Pro Tip: MeshLab's interface can look a bit overwhelming at first glance. Don't let it scare you. For just viewing a model, focus on using your mouse to rotate and zoom. You can ignore all the complex menus until you actually need them.

Open-Source Power for Linux Users

The Linux world is all about powerful, open-source software, and 3D tools are no different. While you won't find a single default viewer across every Linux distribution, you have easy access to some of the best applications out there.

- Blender: I know what you're thinking—Blender is a full-blown 3D creation suite. And it is, but that also makes it an incredible STL viewer. It can handle massive, complex files without breaking a sweat. Just open Blender and navigate to

File > Import > Stl (.stl). - FreeCAD: For anyone coming from an engineering or CAD background, FreeCAD is a perfect fit. It’s a parametric 3D modeler that opens STLs natively and comes equipped with precise tools for measurement and analysis.

Getting them installed is usually just a single command line away, depending on your package manager. For example, on Debian or Ubuntu-based systems, you'd just run sudo apt-get install blender. Both are great additions to your toolkit if you plan on doing more with 3D models down the road.

Why Your Browser Is the Best STL Viewer You Have

Think about this: you can open a complex 3D model with the same easy click you use for a new browser tab. That’s not a hypothetical—it’s exactly what modern web-based STL viewers let you do, and it’s a huge reason you might not need to install any dedicated software at all.

This whole approach just cuts out the friction. No installers to run, no software nagging you for updates, and no programs eating up precious hard drive space. It's a lifesaver for quick design reviews, especially if you're on a computer where you can't install apps, like at a public library or on a locked-down work laptop.

The Power of Drag and Drop

What makes browser-based tools so great is their immediacy. Most of them work on a simple drag-and-drop principle. You just find your .stl file, drag it into the browser window, and boom—it’s there, ready for you to inspect. You can rotate, zoom, and pan around the model from any angle to get a complete picture without any fuss.

This also makes collaboration incredibly simple. Instead of telling a colleague, "Hey, can you install this specific program just to look at my file?" you just send them a link. They can open it, view the model, and give you feedback in seconds, no matter their technical skill or what software they have installed.

Many of these tools also keep your privacy in mind. For example, top browser extensions like the ShiftShift 3D Model Viewer process your files locally. This means your potentially sensitive design files are never uploaded to some random server. All the rendering and interaction happens right on your machine, which is a massive security win.

Here’s a look at how clean a browser-based viewer interface can be.

This screenshot shows a beautifully simple interface. The 3D model takes center stage, free from the overwhelming clutter of menus and toolbars you'd find in professional CAD software.

Key Insight: Browser-based viewers completely open up access to 3D models. They tear down the technical barriers, allowing anyone—from clients to non-technical team members—to interact with a design using the one tool everyone already has open: their web browser.

When to Choose a Browser Viewer

So, when is this the right move? This method is perfect for a bunch of common situations that pop up all the time, whether you're a professional or a hobbyist.

- Quick Verification: You just downloaded a model from a site like Thingiverse and want to make sure it’s the right one before sending it to your slicer.

- Collaborative Reviews: You need fast feedback from a project manager or a client who doesn’t have—and frankly, doesn’t need—a full-blown CAD suite.

- Working on a Restricted Computer: You’re on a machine that prevents software installation, making a browser-based tool your only real option.

- Occasional Use: You only deal with STL files every now and then and don't want to clutter your system with an app you barely use.

For anyone who needs a fast, reliable way to check 3D models, knowing how to pop an STL file open in your browser is an essential skill. You can learn more about how a modern 3D model viewer can simplify your workflow in our detailed guide.

Moving Beyond Viewing to Editing and Printing

Opening an STL file to see your model is just the beginning. The real fun starts when you need to make a change. Maybe a part needs a slight tweak to fit just right, or you've downloaded a model that isn't quite perfect. This is where you move from just looking at a file to actually working with it, and your workflow will branch out depending on whether you're editing, sculpting, or getting ready to print.

Making that leap from passive viewing to active creation is a critical step. A simple preview won't tell you if a model is "watertight" for printing or if its dimensions are accurate enough for a real-world application. For that, you need to roll up your sleeves and get into the right software.

From Viewer to CAD Software

What if you need absolute precision? Say, changing a hole's diameter by a mere 0.2mm or adjusting a mounting bracket. This is a job for Computer-Aided Design (CAD) software. An STL file is basically a shell made of countless triangles, which makes it clumsy for these kinds of exact modifications.

Programs like Autodesk Fusion 360 or FreeCAD are built for this. They can convert that triangle mesh into a solid body, letting you use parametric tools to make precise, history-based changes. It’s the difference between being a sculptor pushing clay around and an engineer defining exact dimensions.

My Two Cents: Reach for CAD software whenever dimensional accuracy is paramount. It’s the go-to for mechanical parts, functional prototypes, or any design where precise measurements are everything.

Fixing and Sculpting with Mesh Editors

Sometimes, the model itself is the issue. You might download a file from an online repository only to find it has holes in its mesh, or maybe you want to make more artistic, organic changes. For this kind of work, a specialized mesh editor is your best friend.

Tools like Meshmixer or the sculpting features in Blender are perfect here. They work directly with the STL’s triangular geometry, giving you powerful capabilities to:

- Repair Holes: Automatically find and patch gaps to make a model "watertight" so it can actually be printed.

- Sculpt Details: Add, smooth, or texturize surfaces in a way that feels more like working with digital clay.

- Combine Models: Merge two separate STL files into a single, cohesive object.

This is an essential part of the workflow for preparing models for 3D printing and for creating complex, artistic designs that aren't bound by strict geometric rules. This expertise is also foundational in fields like construction, where professionals leverage 3D models with augmented reality in construction to overlay detailed plans onto a real jobsite.

Preparing for Print with Slicer Software

Once your model is edited, repaired, and ready to go, there’s one final hurdle before it becomes a physical object: slicing. A slicer is the software that translates your 3D model into a language your 3D printer can actually execute.

Programs like Ultimaker Cura or PrusaSlicer take your finished STL file and chop it into hundreds or thousands of thin, horizontal layers. Here, you'll dial in all the critical print settings—layer height, print speed, infill density, and support structures. The software then spits out a G-code file, which is the set of precise instructions that tells the printer head where to move and when to extrude plastic.

The STL format has been the industry standard in additive manufacturing since the late 1980s, leading to a massive ecosystem of compatible tools. This widespread adoption means that virtually every slicer on the market knows exactly how to handle an STL file, making it a reliable workhorse for creators everywhere.

Working Through Common STL File Problems

Hitting a snag when you try to open an STL file is frustrating, but don't worry—the fix is usually pretty simple. Nine times out of ten, the issue is with the file itself, not the software you're using. A classic culprit is a corrupted file from a download that didn't quite finish. Even a tiny hiccup in your internet connection can leave you with a file that looks right but is actually unreadable.

Another common stumbling block is the old Binary vs. ASCII format issue. While most modern tools can handle both just fine, some older or highly specialized programs might throw an error if you feed them the wrong type. It's a quick thing to check if a file opens on one machine but not another.

The Dreaded "Non-Manifold" Error

One of the most common—and intimidating—warnings, especially for 3D printing, is an error about "non-manifold" or "not watertight" geometry. So, what does that even mean?

Imagine your 3D model is a bottle you need to fill with water. If there are any holes in its surface, no matter how small, the water will leak out. That's a non-manifold model.

For a 3D printer, these holes are a dealbreaker. The slicer software gets confused because it can't figure out what's "inside" and what's "outside" the object. This almost always leads to a jumbled mess on the print bed. You'll see this a lot with models grabbed from online libraries, as they aren't always designed with perfect, gap-free surfaces.

A Pro Tip From Experience: Don't sweat a non-manifold error. Tools like Autodesk Meshmixer or even the built-in 3D Builder on Windows have fantastic, often one-click, repair functions. They can find and patch those tiny holes for you, turning your leaky model into a solid, printable object in just a few moments.

Getting your file fixed is usually just a few clicks away:

- First, import the troublesome STL file into your repair tool of choice.

- Next, look for an "inspect" or "analyze" function and run it.

- The software will highlight the problem areas and usually suggest an automatic fix. Just apply it.

- Finally, export the newly repaired, watertight STL, and you're good to go.

Got Questions About STL Files? We’ve Got Answers.

When you're working with 3D models, a few questions always seem to pop up about the trusty STL file format. Getting these sorted out can save you a ton of headaches and help you get from design to print much more smoothly.

So, let's dive into some of the most common queries I hear.

Why Is My STL File Just One Solid Color?

This is probably the number one question. People open their model and wonder where the beautiful textures and colors went. The short answer is: they were never there.

The standard STL format is color-blind. It only describes the surface geometry of a 3D object—basically, a huge collection of interconnected triangles. It doesn't store any information about color, texture, or material properties.

Can I Actually Edit an STL File?

Yes, but it depends entirely on your software. You can open and view an STL in dozens of programs, but that doesn't mean you can edit it.

- Simple viewers (like the built-in ones in Windows or macOS) are just for looking. You can rotate and zoom, but that’s it.

- To actually modify the model, you need a dedicated mesh editor like Blender or Meshmixer.

- Alternatively, a CAD program like Fusion 360 can often convert the STL mesh into a solid body, which is much easier to work with for precise engineering changes.

What’s Making My STL File So Huge?

File size can be a real pain, especially when you're trying to share designs. If your STL is massive, it’s usually due to one of two things: model complexity or file format.

A super-detailed model with millions of tiny triangles will naturally be a large file. But the real culprit is often the format. An ASCII-formatted STL, which stores data as plain text, can easily be 5-6 times larger than its far more efficient Binary equivalent.

My Pro Tip: Always, always save or export your STLs in the Binary format. It's smaller, loads faster, and is the professional standard for a reason. ASCII is really only useful if you need to manually inspect the file in a text editor, which is a rare scenario.

Can I Just Send an STL File Straight to My 3D Printer?

Not quite. Think of the STL file as the architectural blueprint. It shows what the final object should look like, but it doesn't contain the step-by-step instructions a printer needs to build it.

That's where "slicer" software comes in. A slicer (like Cura, PrusaSlicer, or Simplify3D) takes your STL, "slices" it into hundreds or thousands of thin horizontal layers, and generates the machine-readable instructions, known as G-code. The G-code is what actually tells your 3D printer how to move, when to extrude plastic, and at what temperature.

To make things a bit clearer, here’s a quick summary of the most common questions.

FAQ Quick Reference

| Question | Short Answer |

|---|---|

| Do STLs have color or texture? | No, the STL format only stores the 3D model's surface geometry. |

| Can I edit any STL file? | You need specific software like a mesh editor (Blender) or a CAD program. |

| Why is my STL file so large? | It's likely a complex model saved in the inefficient ASCII format instead of Binary. |

| Is an STL file ready for 3D printing? | No, it must be processed by "slicer" software first to create G-code. |

Hopefully, that clears up some of the mystery around the STL format! Understanding these fundamentals is key to a smoother 3D workflow.

If you're looking for a hassle-free way to preview your 3D models right in your browser, I highly recommend the 3D Model Viewer extension from ShiftShift Extensions. It’s a fantastic tool that opens both ASCII and Binary STL files instantly, keeping your work private and secure on your own machine.