A Practical Guide to Using a STEP STL Converter

Master the step stl converter process. Learn to choose the right settings, troubleshoot common issues, and select the best tools for perfect 3D prints.

الإضافات الموصى بها

If you've ever designed a part in a CAD program and then tried to 3D print it, you've run into a fundamental translation problem. Your design software creates a STEP file, which is a perfect mathematical model. But your 3D printer needs an STL file, which is a simpler mesh made of triangles. A step stl converter is the essential tool that bridges that gap.

Getting this conversion right is everything. The quality of that translation from a smooth, precise STEP model to a faceted STL mesh directly dictates the accuracy, detail, and surface finish of your final print.

Bridging Design and Reality with a STEP STL Converter

Think of it this way: a STEP file describes a perfect sphere using a single, elegant mathematical formula. Your 3D printer can't work with that. It needs a set of simple, direct instructions. An STL file provides those instructions by approximating the sphere's surface with hundreds or even thousands of tiny, flat triangles.

The converter is the interpreter that turns the complex language of engineering design into the practical, step-by-step language of a 3D printer. This isn't just a format swap; it's a complete reimagining of the object's geometry.

Why This Conversion Matters So Much

The stakes are high because a poor conversion leads to a poor print. A low-quality STL might have gaps, misplaced triangles, or a blocky finish that looks nothing like your original design.

- For Engineers: A solid conversion workflow means moving from a design in Fusion 360 or SolidWorks to a physical prototype on your desk in hours, not days. It dramatically speeds up iteration and product development.

- For Hobbyists: It unlocks a world of possibilities, allowing you to grab complex mechanical parts online, tweak them, and print them without needing expensive, professional-grade software for the conversion.

To really get why this matters, it helps to understand what is Additive Manufacturing as a whole. It’s the technology that breathes life into these digital files, making the entire design-to-object process possible.

To make the distinction clearer, here’s a quick breakdown of how these two formats differ at their core.

STEP vs STL Quick Comparison

This table highlights the fundamental differences between the precise, mathematical world of STEP and the practical, mesh-based world of STL.

| Attribute | STEP (Standard for the Exchange of Product model data) | STL (Standard Tessellation Language) |

|---|---|---|

| Geometry | Defines objects using precise mathematical curves and surfaces (NURBS). It's an exact representation. | Approximates surfaces using a mesh of interconnected triangles (tessellation). It's an approximation. |

| File Size | Generally smaller and more efficient for complex, curved models. | Can become very large, as more triangles are needed to represent smooth surfaces accurately. |

| Accuracy | Lossless. The geometry is mathematically perfect and can be scaled infinitely without losing detail. | Lossy. The resolution is fixed by the number of triangles. Zooming in will reveal the flat facets. |

| Editability | Highly editable in CAD software. You can modify features, dimensions, and relationships. | Difficult to edit. Modifying the mesh is complex and often requires specialized software. |

| Use Case | Professional CAD design, engineering, manufacturing, and data exchange between different systems. | Primarily for 3D printing, rapid prototyping, and computer-aided manufacturing (CAM). |

Understanding these differences shows why the conversion isn't just a "Save As" operation—it's a critical translation where you trade mathematical perfection for printable practicality.

The Growing Need for Efficient Tools

With the 3D printing market booming, the need for reliable converters is more urgent than ever. The market was valued at USD 30.55 billion in 2025 and is on track to hit an incredible USD 168.93 billion by 2033, reflecting a massive 23.9% compound annual growth rate.

This explosion in use means more people are hitting this conversion bottleneck. A good tool makes the workflow smooth, while a bad one creates headaches.

This guide will walk you through the different ways to handle this conversion, from powerful desktop software to nimble, privacy-first tools that run right in your browser. Knowing the pros and cons of each will help you pick the right workflow, whether your top priority is absolute precision, raw speed, or keeping your designs secure.

Dialing in the Perfect Conversion Settings

Moving from a STEP file to an STL isn't just a simple "Save As" operation. It's a translation process where you're turning a perfect, mathematically-defined solid into a mesh of simple triangles that a 3D printer can actually understand.

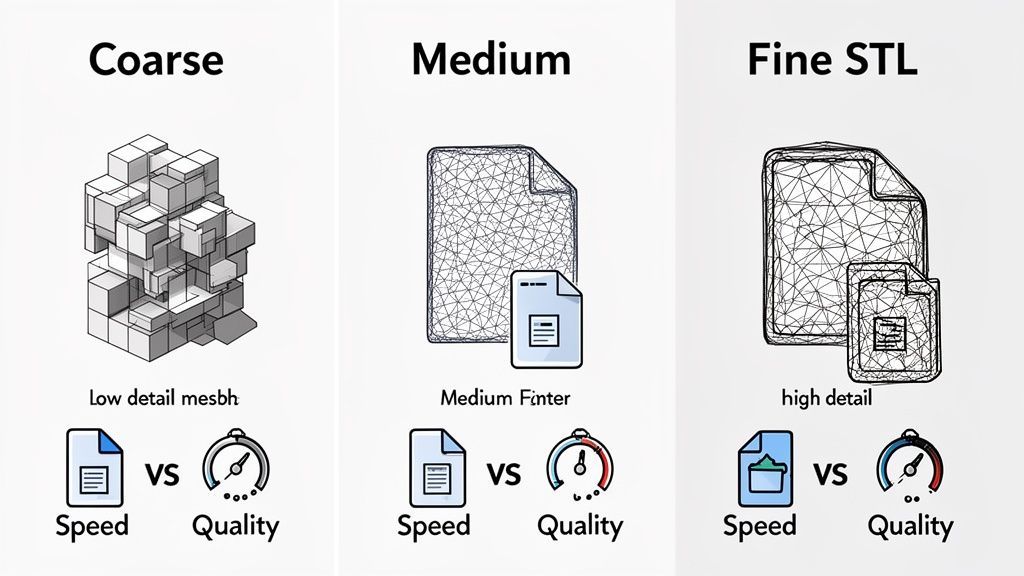

The decisions you make here are critical. They determine the final quality of your printed object. Think of it less like saving a document and more like developing a photograph—the settings you choose now will dictate how sharp and detailed the final picture is. Your goal is to find that sweet spot between a beautiful, smooth surface and a file size that won't bring your slicer to its knees. Too few triangles, and your model will look blocky; too many, and you’re left with a massive file that’s a pain to handle.

Mastering Mesh Resolution

The process of turning a STEP file’s smooth curves into an STL's triangles is called tessellation. Any decent converter will give you control over this, usually through two key settings: chordal deviation and angular tolerance.

Chordal Deviation (sometimes called linear deviation) sets the maximum allowable distance between the original STEP surface and the face of an STL triangle. A smaller value means a more accurate surface, but at the cost of more triangles and a larger file.

Angular Tolerance (or angular deviation) dictates the maximum angle between adjacent triangles. This is your go-to setting for capturing fine details on tightly curved surfaces. A smaller angle forces the software to use more triangles to approximate the curve, preserving those subtle shapes.

For something like a functional mechanical bracket where dimensional accuracy is everything, you’ll want to prioritize a low chordal deviation. But if you're printing a detailed miniature figurine, a smaller angular tolerance becomes much more important to keep the curves from looking like jagged polygons.

Finding the Right Balance

There is no single "best" setting here. The ideal resolution depends entirely on what you're making.

- For rapid prototypes: Go with a coarser mesh (higher deviation values). It converts faster, the file is smaller, and it prints quicker. This lets you test form and fit without waiting ages for a high-detail print to finish.

- For production-quality parts: You’ll need a much finer mesh (lower deviation values) to get a smooth surface finish that truly represents the original CAD design, especially for models with complex, organic shapes.

This trade-off is one of the main challenges of any step stl converter. For instance, engineers at DigiFabster noticed that their default STL exports made detailed STEP models look "raw and lumpy." After a ton of testing, they landed on a standard 20-micron tessellation setting. While this blew up their average file size by 500%, it produced renders smooth enough for their professional manufacturing needs. You can read more about their journey to balance file size and quality.

Choosing Your Output Format: Binary vs. ASCII

After dialing in the mesh, you'll often see a choice between two STL formats: binary and ASCII. The difference seems small, but it has a massive impact on file size and usability.

- Binary STL: This is the one you want 99% of the time. It stores the triangle data in a compact, machine-readable code. The resulting files are tiny—often 4-5 times smaller—and are processed much faster by slicers. For virtually all 3D printing, this is the way to go.

- ASCII STL: This format stores the same data in plain text. You could literally open it in Notepad and read the coordinates. While this is useful for debugging or manual editing, it creates dramatically larger files. Unless you have a very specific, nerdy reason to do so, avoid this format.

The takeaway is simple: Always export as a binary STL. It saves space, loads faster, and is the industry standard for good reason.

Verifying Units and Scale

One last, crucial setting to check is the unit of measurement. There’s nothing more frustrating than importing your model into a slicer only to see it appear as a microscopic dot or a gigantic object filling the whole build plate.

This classic problem happens when the exporting software and the slicer disagree on whether the model’s units are in millimeters or inches. The vast majority of 3D printing workflows are based on millimeters (mm). Before you hit export, double-check that your CAD program or converter is set to output in millimeters.

If you do open an STL and it's the wrong size, the first thing to check is the scale factor. It will almost certainly be off by a factor of 25.4—the magic number for converting inches to millimeters. While you can easily fix this in your slicer, getting it right during the conversion saves you that extra, annoying step.

Finding the Right STEP to STL Conversion Tool

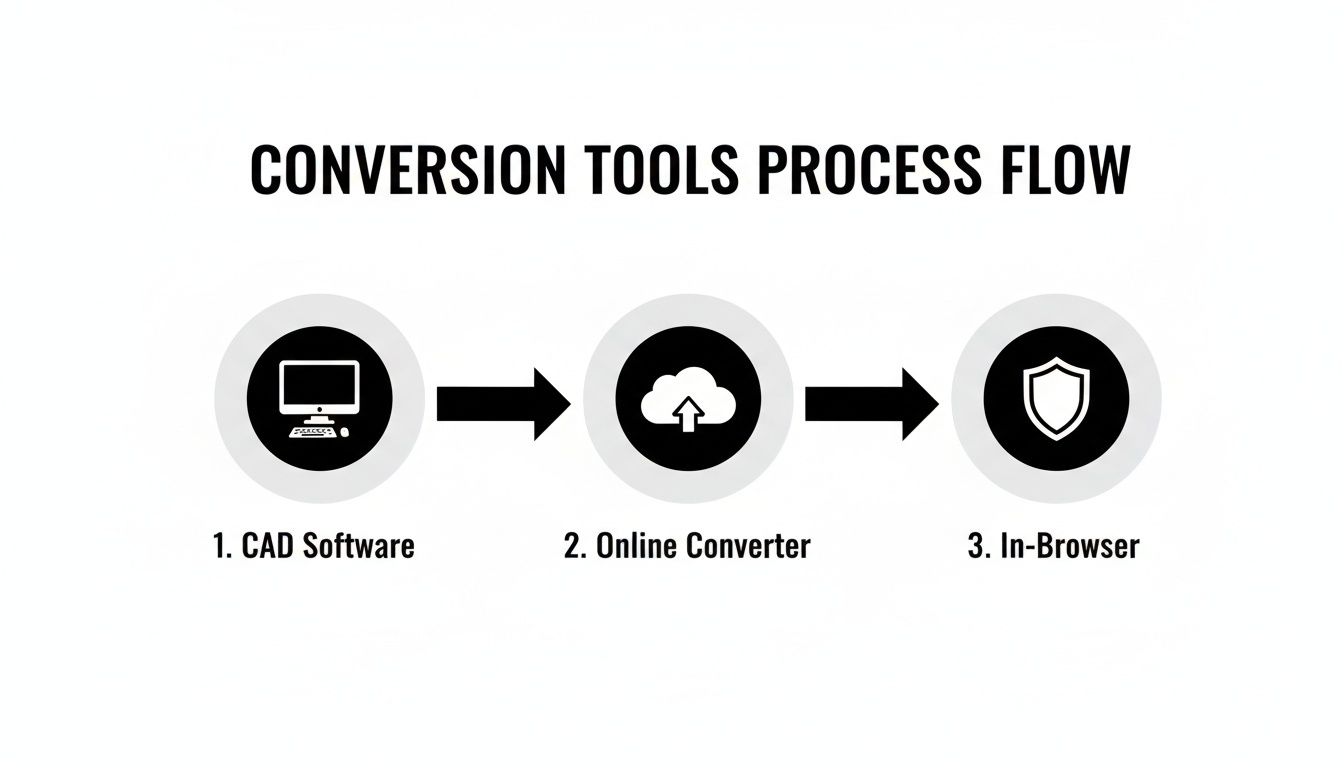

It can feel like you're drowning in options when you need to convert a STEP file to an STL. Do you fire up a heavy-duty CAD program, use a quick online tool, or is there something in between? The truth is, the best step stl converter for you comes down to what you’re trying to accomplish.

Choosing the right tool isn’t just about getting a usable file; it's about finding the smartest path for your workflow. A hobbyist printing a cool figurine has completely different needs than an engineer prototyping a confidential new product. Let's walk through the main options to figure out which one fits you best.

Professional Desktop CAD Software

If you're an engineer or designer already living in a professional CAD environment, the most straightforward route is to use the tools you already have. Programs like FreeCAD, Autodesk Fusion 360, and SolidWorks all have powerful, built-in exporters that handle STEP to STL conversions beautifully.

The huge win here is control. These programs give you direct, granular access to all the critical mesh settings—chordal deviation, angular tolerance, you name it. You can dial in the output with surgical precision, guaranteeing the final STL is perfectly suited for your 3D printer and the part's specific geometry.

But all that power comes with a price: a steep learning curve and hefty system requirements. If you aren't already a CAD user, downloading and learning a program like FreeCAD just for a one-off conversion is like using a sledgehammer to crack a nut. It’s total overkill.

Command-Line Utilities for Automation

For developers, power users, or anyone staring down a mountain of files to convert, command-line interface (CLI) tools are a game-changer. These are lightweight programs you run from a terminal, which lets you script and automate the entire process from start to finish.

Just imagine you have a folder with 100 STEP files that all need to be converted using the exact same high-resolution settings. Doing that by hand would be mind-numbing. With a CLI tool, a simple script can chew through the entire folder, apply your conversion rules, and spit out perfect STLs while you grab a coffee. For manufacturing and professional workflows, this is an incredible time-saver.

Of course, this approach assumes you're comfortable working in a command-line environment. It’s far from a point-and-click solution, but for anyone who needs to process files at scale, the efficiency is unbeatable.

The Convenience and Risks of Online Converters

A quick Google search for "step stl converter" will flood your screen with websites promising instant, free conversions. The workflow is temptingly simple: upload your STEP, click a button, and download the STL. For simple models that aren't sensitive, you can’t beat the convenience.

But that convenience comes with a massive hidden cost: privacy.

Every time you upload a design to a third-party server, you lose control of your intellectual property. For a personal project or an open-source model, that might be a risk you're willing to take. But for a proprietary design, client work, or a sensitive prototype? It's a deal-breaker.

Beyond the security nightmare, online converters usually offer a laughably small amount of control. You might get a few presets like "low, medium, high," but you lose the ability to fine-tune the mesh. You’re often left with an STL that's either too chunky and low-poly or monstrously huge for no good reason.

In-Browser Tools: The Best of Both Worlds

A newer and much smarter category of tools is emerging: local, in-browser converters. These work on a completely different principle. Instead of uploading your file to a server in some unknown location, all the conversion magic happens right inside your web browser, on your own machine. Your data never leaves your computer.

This approach gives you the click-and-go simplicity of a web tool combined with the robust security of a desktop app. You get a clean, friendly interface without installing a single piece of software, all while keeping your designs completely private.

Tools like ShiftShift Extensions are built around this privacy-first model. Its built-in 3D model viewer and converter lets you drag and drop a STEP file, inspect it from every angle, and convert it to STL without a single byte of your model ever hitting the internet. This is the perfect solution for anyone who needs a quick, secure conversion without the overhead of pro CAD or the risks of an online service.

How to Choose the Right Path

To help you decide, I've put together a quick comparison. Just think about what matters most for your project, and the right tool will quickly become clear.

Comparison of STEP to STL Conversion Methods

| Conversion Method | Best For | Key Advantage | Key Disadvantage |

|---|---|---|---|

| Professional CAD | Engineers, designers, and users needing maximum precision. | Complete control over every conversion setting for optimal quality. | High learning curve, requires powerful hardware, and is often expensive. |

| Command-Line Tools | Developers and users needing to process many files at once. | Unbeatable for batch processing, automation, and script integration. | Requires technical knowledge and is not user-friendly for single files. |

| Online Converters | Quick, non-sensitive conversions for hobbyist projects. | Extremely easy to use and accessible from any device with a browser. | Major privacy and security risks; very limited control over settings. |

| In-Browser Tools | Users who prioritize privacy, speed, and ease of use. | Secure, local processing with no data uploads; simple and fast. | May not offer the advanced, granular controls of full CAD software. |

At the end of the day, the world of step stl converter tools has an option for everyone. By understanding the trade-offs between control, convenience, and privacy, you can confidently pick the method that makes the most sense for your project and its security needs.

How to Validate and Troubleshoot Your STL File

So you've converted your STEP file. Great! But don't fire up the 3D printer just yet. Converting a file is one thing; making sure it’s actually printable is another. This quick quality check is your last line of defense against a failed print, saving you hours of frustration and a spool of wasted filament.

Think of an STL file as a digital sculpture made of tiny triangles, all stitched together. If even a few of those triangles are missing, facing the wrong way, or just plain messed up, your printer won't know what to do. Let's walk through how to spot these gremlins before they ruin your day.

The path you take to convert your file—whether it's through full-blown CAD software or a quick online tool—can influence the kinds of errors you might see. Each method has its quirks.

This is why a quick post-conversion check is always a good idea, no matter which tool you used.

Checking for a Watertight Model

The absolute number one rule for a printable STL is that it must be watertight—also called "manifold." Imagine your model is a bucket. If it has any holes, it can't hold water. Your 3D slicer thinks the same way; it needs a perfectly sealed object to understand where the "inside" and "outside" are.

Many modern slicers like PrusaSlicer or Ultimaker Cura are smart enough to spot and sometimes fix these holes automatically. But for a more thorough job, a tool like Autodesk Meshmixer is invaluable. It will visually pinpoint any gaps and give you the tools to patch them up properly.

Correcting Surface Normals

Every triangle in your STL mesh has a direction—it faces either "in" or "out." This direction is its surface normal. If some normals get flipped during conversion and point inward, the slicer gets confused and treats that part of the model like a hollow space, leading to bizarre gaps or missing sections in your print.

A model with flipped normals is one of the most common—and confusing—problems you'll encounter. It might look perfectly fine in a simple viewer, but it will slice into a garbled mess. Always use a viewer that can visualize normals if you suspect an issue.

Thankfully, the fix is usually simple. Most 3D programs, including Meshmixer and even Blender, have a function like "Recalculate Normals" or "Flip Normals" that can unify everything with a single click.

Fixing Non-Manifold Edges

This one's a bit more complex. Non-manifold geometry happens when your model has edges that couldn't exist in the real world. A classic example is when an edge is shared by more than two triangles, creating a T-junction where the slicer can't determine what's inside or outside.

Other non-manifold errors include internal faces trapped inside the model or edges that just float, connected to nothing. These ambiguities are a recipe for disaster in a slicer. A good mesh repair tool will help you find these problem spots, letting you delete the bad geometry or properly separate the parts into their own distinct shells.

Common Troubleshooting Scenarios

Beyond the tricky mesh errors, a few other common headaches can pop up. Here are some of the usual suspects and how to handle them:

Problem: My model looks blocky or faceted.

- Solution: Your export resolution was too low. Head back to your converter and export the file again, but this time use a lower chordal deviation or angular tolerance. This will create a finer, more detailed mesh.

Problem: The file is either microscopic or gigantic when I import it.

- Solution: This is almost always a units mismatch. You likely exported in inches when your slicer expected millimeters. You can either re-export with the correct units (millimeters is the standard for 3D printing) or just scale the model in your slicer by a factor of 25.4 to convert from inches to mm.

Problem: My slicer is taking forever to process the file.

- Solution: The mesh is too dense! Your conversion settings were too high, creating a massive file with millions of triangles you don't actually need. Re-export with slightly higher deviation values to reduce the polygon count. If you work with lots of files, a lightweight 3-D model viewer can help you inspect them quickly before you even send them to the slicer.

Automating Conversions with Advanced Workflows

For anyone working in engineering or product design, converting files one by one is a massive time-waster. That manual loop—open a STEP, tweak settings, export to STL, save, repeat—is fine for a single prototype. But when you’re staring down an assembly with dozens, or even hundreds, of components? It becomes a serious production bottleneck. This is where you have to scale your workflow. It’s not just about convenience; it’s a necessity.

Automating the STEP to STL conversion process gets you out of the repetitive grunt work, guarantees every model is converted with the same settings, and frees you up for design challenges that actually matter. By leaning on scripting and command-line interfaces, you can turn this tedious chore into a completely hands-off operation.

Tapping into the Command Line for Batch Processing

Instead of clicking through a graphical interface for every single file, automation workflows use the raw power of command-line tools. These are lightweight programs that run conversions based on simple text commands, which makes them perfect for scripting. You can write a small script that points to a folder full of STEP files and tells the converter to process all of them in one go.

Let's say you need to get an entire product assembly ready for 3D printing. A simple script could handle all of this for you:

- Run through every

.stepor.stpfile in your project folder. - Apply a pre-defined set of high-resolution mesh settings for the final production parts.

- Maybe even generate a second, low-res set for quick, draft-quality validation prints.

- Neatly organize all the finished STLs into an "output" directory, possibly renaming them based on a specific convention.

This approach ensures every model is converted with identical, error-free settings. That's a level of consistency that's nearly impossible to maintain when you're doing it all by hand. For a deeper dive into automating business processes like this, check out this complete guide to workflow automation software; it offers some great insights into the tools available.

A Practical Example with Python

Python is a fantastic choice for this kind of automation, thanks to libraries that can directly interact with CAD kernels. For instance, using a library built on a powerful geometry engine like OpenCASCADE, you can write a script that manages the entire conversion process without ever opening a CAD program.

Here’s a conceptual idea of what a simple Python script might look like:

A conceptual Python script for batch conversion

import os from some_cad_library import STEPReader, STLWriter

Define where your files are and where they should go

input_folder = "/path/to/your/step_files/" output_folder = "/path/to/your/stl_files/"

Set your desired mesh quality once

mesh_deflection = 0.01 # A fine setting for high detail

Loop through all files in the input folder

for filename in os.listdir(input_folder): if filename.endswith(".step") or filename.endswith(".stp"): step_path = os.path.join(input_folder, filename)

# Read the STEP model

model = STEPReader.read(step_path)

# Create the mesh using your setting

model.tessellate(mesh_deflection)

# Figure out the new output filename

stl_filename = filename.replace(".step", ".stl").replace(".stp", ".stl")

stl_path = os.path.join(output_folder, stl_filename)

# Write the final STL file

STLWriter.write(model, stl_path)

print(f"Successfully converted {filename} to STL.")

A simple script like this automates a workflow that would otherwise burn hours of clicking. The principles of automation apply across all sorts of data challenges, as you can see with something like a CSV to Excel converter, where scripts save you from mind-numbing manual work.

Integrating into Modern Development Pipelines

The real magic happens when you plug these scripts into bigger development systems, like a Continuous Integration/Continuous Deployment (CI/CD) pipeline. This idea, borrowed from the software world, works brilliantly for hardware design, too.

Imagine this: every time a designer commits a change to a STEP file in a version control system like Git, it automatically triggers your conversion script. That script instantly generates a new STL, which could then be fed into an automated analysis tool, validated by a slicer, or even sent directly to a 3D printer for a fresh prototype.

This setup creates a seamless "push-to-print" workflow. It closes the gap between a design change and a physical part in your hands, letting hardware teams iterate with the kind of speed and agility that software teams have had for years. By embracing automation, the STEP to STL converter evolves from a simple utility into a crucial part of a modern, efficient engineering ecosystem.

Where Conversion is Headed: In-Browser, Private, and Integrated

Anyone who's been in this field for a while has noticed a clear trend: we're moving away from clunky, install-heavy desktop software. The future of 3D model conversion is happening right in your browser, cutting out the hassle of downloads and updates. This isn't just about convenience; it’s a massive shift towards speed, accessibility, and—most importantly—privacy.

A privacy-first mindset is no longer a "nice-to-have." It's the new standard. Engineers and designers constantly need to view, check, and convert models, but uploading sensitive IP to a random cloud server just isn't an option. This is where in-browser tools that run locally on your machine are changing the game. You get the ironclad security of desktop software with the dead-simple access of a web app.

Secure Workflows are Becoming the Norm

This whole movement is being supercharged by the explosion in 3D printing, especially for rapid prototyping. We're looking at a market projected to jump from USD 19.8 billion in 2023 to a staggering USD 135.4 billion by 2033. That kind of growth creates a huge demand for better, faster conversion tools. For more on this, check out the data on 3D printing's market trajectory.

Tools like ShiftShift Extensions are built for this reality. They give you a local 3D viewer and a step stl converter that does all the work right there in your browser. This means you can iterate on a design instantly without ever sending your file across the internet.

The big takeaway is simple: your workflow should protect your intellectual property by default. Choosing tools that operate locally isn't just a feature—it's a critical security practice for modern design and engineering.

Ultimately, the best tools are the ones that fit seamlessly into how you already work. Command-palette-driven tools are a perfect example, putting a secure step stl converter just a keyboard shortcut away. This approach doesn't just make you more productive; it keeps your data safe and opens up powerful capabilities to everyone, from seasoned engineers to weekend makers. This principle of secure, browser-based tools isn't limited to 3D models—you can see a similar trend in our guide to the best free PDF converter software.

Common Questions and Quick Answers

When you're first getting into converting STEP files, a few questions always seem to pop up. Getting these sorted out early on can save you a ton of headaches and prevent prints from failing later.

Can I Convert an STL File Back to a STEP File?

The short answer? Not really, at least not easily or cleanly. While some advanced reverse-engineering software claims to do it, turning an STL back into a STEP is a messy, complex process that almost never gives you a perfect result.

An STL is just a mesh of triangles—it’s a surface model with no real "intelligence." It doesn't contain the rich, precise design history that a STEP file does. Trying to rebuild that parametric data from a simple mesh is like trying to reconstruct an architect's original blueprint from a scanned photo of the finished building. You'll get something, but it's likely to be flawed and will require a ton of manual cleanup.

Why Is My Converted STL File So Large?

This is a classic—and totally normal—part of the conversion process. A STEP file is a marvel of efficiency; it describes complex, curved geometry using pure mathematical formulas. An STL file, on the other hand, has to approximate those perfect curves by stitching together thousands (or even millions) of tiny, flat triangles.

The smoother you want your final model to look, the higher you'll set the resolution. This forces the converter to generate a massive number of triangles to create that illusion of a perfect curve, which naturally makes the file size explode.

Pro Tip: Always, always export your STL in the binary format, not ASCII. A binary STL is dramatically smaller—we're talking four to five times smaller—and your 3D slicer will be able to process it much faster. It's the standard for a reason.

Does Converting from STEP to STL Reduce Quality?

Yes, technically, some precision is always lost in the translation, but the key is that you control how much. The process of converting a smooth mathematical model into a triangular mesh is called tessellation, and it’s fundamentally an approximation.

Think of it like trying to draw a perfect circle using only a series of tiny straight lines. You can control how short those lines are. By tweaking settings like chordal deviation and angular tolerance in your converter, you can make the "lines" (the edges of the triangles) so small that the loss of quality is completely invisible on the final 3D print. It's all about finding that sweet spot between a beautiful, smooth model and a file size that doesn't bring your computer to its knees.

Unlock a world of productivity with ShiftShift Extensions, the all-in-one toolkit for developers, designers, and power users. Instantly access dozens of tools like a secure 3D Model Viewer, file converters, and developer utilities—all from a single command palette, right in your browser. Get started for free at https://shiftshift.app.